The Sustainable Development Goal 12 provides for dealing with natural resources more efficiently. One solution is the circular economy: Sustainable management means harvesting natural resources carefully and using them wisely. Within the meaning of the circular economy, the proportion of secondary raw materials, such as recycled material, should be maximised. The waste generation is to be significantly reduced by prevention, reduction, recycling and reuse.

Good to know

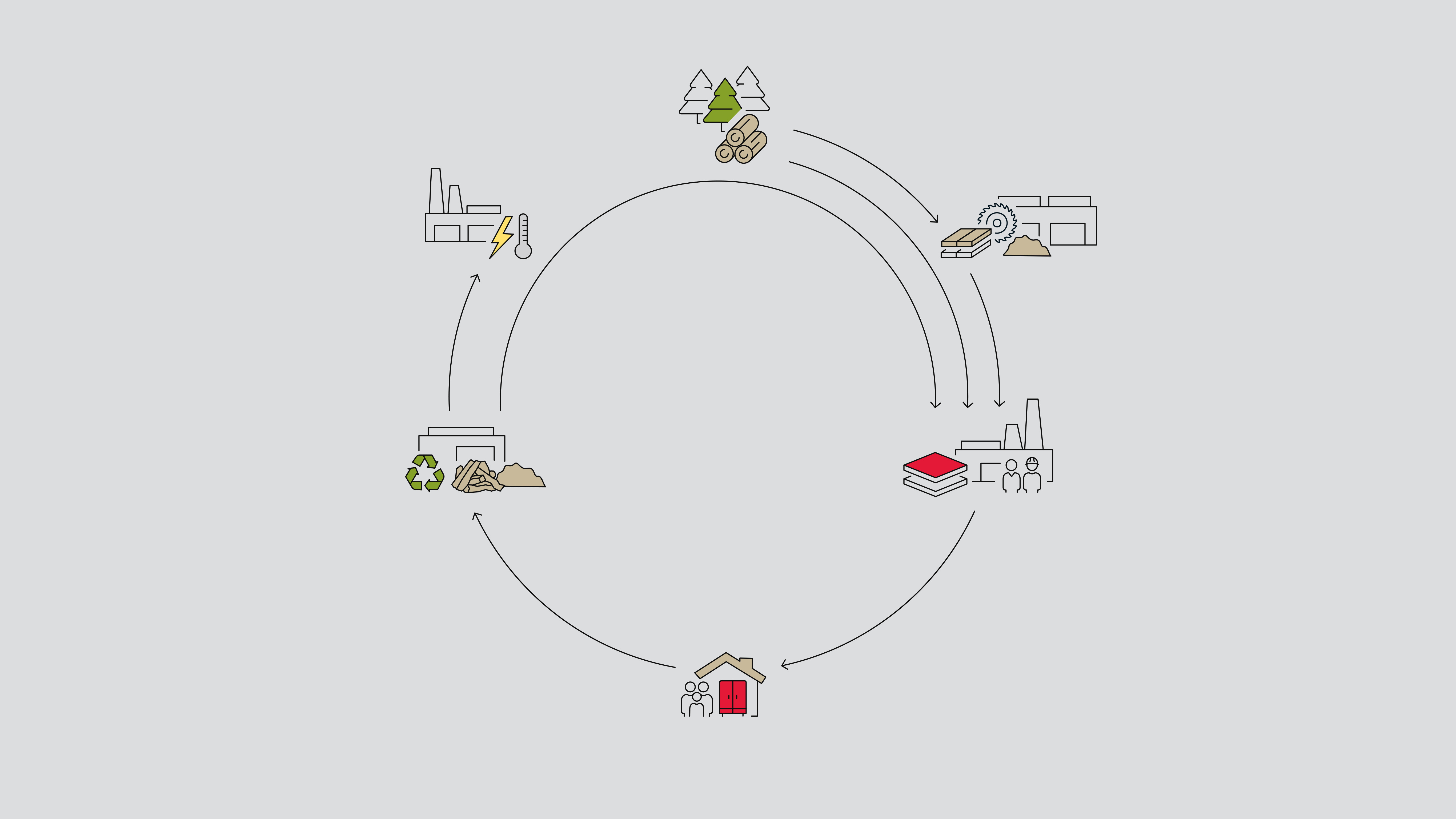

Resource-efficient cycles

From the tree to the product: Our actions focus on the closed material cycle. In doing so, we count on fully integrated plants with short transport routes. We make full use of the valuable resource wood.

Our commitments

The EGGER Group is pursuing the goal of further increasing the recycling rate in its own use of wood. We are making comprehensive investments for this purpose. This is how we make the best possible use of the valuable resource wood.

- Working in closed cycles is a core element of our sustainability strategy.

- We mainly use wood from the circular economy that has already had several lives: This includes recycled wood and by-products from the sawmill industry. We use this to produce high-quality wood-based materials again.

- This recycled wood comes from discarded goods such as old furniture, pallets or board cut-outs.

- We procure the recycled material from qualified waste disposal companies or from our own recycling collection sites.

- We only use suitable material intended for material recycling. Both in the case of recycled wood and the finished product, strict quality standards and quality inspections apply.

- In 1995 we used recycled wood in our production for the first time and have since built up a great deal of expertise.

- Trees absorb CO2

during their growth, and so the carbon remains stored in the wood over its entire useful life. With every chip that is recycled, we are able to further extend this storage effect. This is how we make a contribution to climate protection.

To ensure the supply of recycled wood to our plants, we focus on active backward integration and operate our own recycling collection sites under the name EGGER Timberpak. We would like to further expand this network. This is how we combine resource conservation and raw material security.

- You can see an overview of where we already have recycling collection sites here.

- With this successful concept, we were also able to help create appropriate structures in countries where the recycling of wood was not yet common practice.

- At our Timberpak sites, recycled wood from the respective region is collected, sorted and pre-shredded for transport to our plants. Final processing takes place there.

- To turn the recycled wood into a high-quality board material, special systems are required that process the material in a highly efficient manner. We are continuing to invest heavily in new recycling processing plants at our production sites.

Further information can be found in our Financial and Sustainability Report.

Measures and progress

Every step counts! We have recently implemented these measures on our way to a circular future.